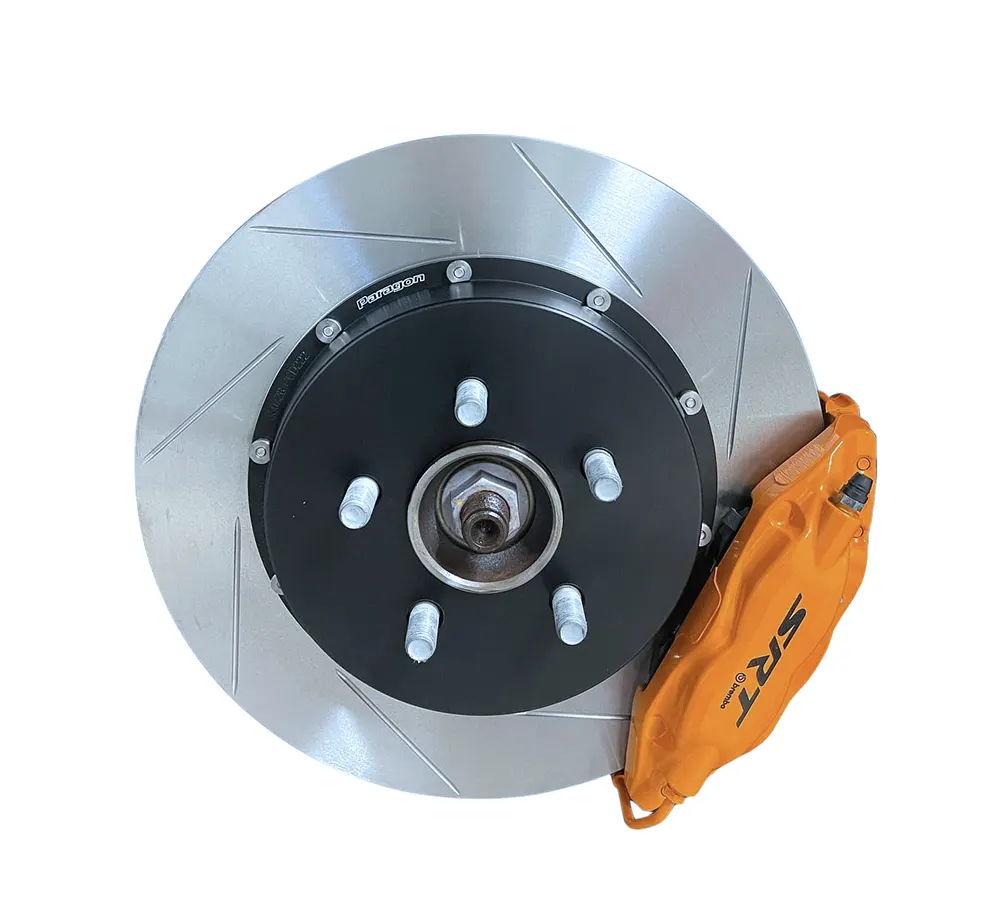

Paragon Performance Brake Discs for Dodge Challenger 6.4 and Hellcat from 2015 to 2023 (350mm), Slotted Design for the Rear Axle

By using Paragon Performance brake discs, you can effectively prevent premature cracking of the standard brake discs on your Dodge Challenger 6.4 / Hellcat during racetrack use or intensive use. Our brake discs not only offer a solution to this problem, but also noticeably improve the pedal feel and modulation of your brakes. With high-quality materials and precision manufacturing, our brake discs guarantee optimum performance and reliability. Put your trust in Paragon Performance and experience a significant increase in braking performance and safety in your Dodge Challenger.

Paragon Performance brake discs for the Dodge Challenger offer impressive performance and reliability. Specifically designed for track use, they ensure superior braking and cooling efficiency. The directional ventilation fins create a suction that channels cool air through the brake disc, improving heat dissipation. This increases resistance to cracking under extreme track conditions. Paragon Performance brake discs are the ideal choice for demanding drivers looking for maximum performance and safety on the racetrack.

The rotor is made of CM-250, a special high carbon cast alloy that ensures optimum bite, thermal properties, high temperature strength and durability.

The rotor rings are heat-treated to relieve stresses in the brake disc and thus prevent deformation and vibration.

They are then turned with a state-of-the-art CBN surface treatment to ensure better running-in with new brake pads.

Vibrations are reduced as the lateral runout of the brake disc is kept within 0.03 mm and the balancing is within 2 grams.

All brake discs have undergone rigorous quality control and testing to ensure that they are fit for purpose.

The two-piece design allows thermal expansion of the brake disc while minimising deformation and ensuring centring of the brake disc to the brake pads.

A slotted brake disc improves braking stability by maintaining a clean contact surface and dissipating the heat and gases generated when the brake pads come into contact with the brake disc.

Slotted brake discs have a decisive advantage over bare brake discs in wet or rainy conditions, as they prevent the formation of water films between the brake pad and the brake disc.

The two-piece Paragon Performance brake discs weigh less than most O.E. brake discs while maintaining thermal load capacity and improve handling by saving unsprung mass.

The Paragon Performance brake discs for the Challenger SRT and Hellcat are made from high-quality 6061-T6 aluminium. Precise CNC milling and subsequent black hard coating / hard anodising give the aluminium pots a non-conductive protective layer. The black colouring is applied after hard anodising and ensures a stylish look. These pots guarantee equivalent performance and durability.

The black hard coating/hard anodising in accordance with Mil-Spec (MIL-A-8625 Type III) does not discolour in extreme heat. The black hard coating/hard anodised surface is harder, thicker, more wear-resistant and scratch-resistant.

The black hard coat/hard anodised finish provides a thick hard coat that offers greater corrosion resistance and low maintenance durability. A black hardcoat/hard anodised finish holds up better when exposed to ultraviolet (UV) light, which is even more important if the vehicle is frequently parked outdoors.

Features:

- Directly usable without any modifications and designed to work smoothly with the OEM ABS and the manufacturer's braking system, while retaining the factory brake preload. Compatible with OEM brake pads or accessory pads with the same pad depth.

- Directional ventilation fins for optimum cooling performance, runs up to 30 % cooler than O.E. brake discs and increases cooling efficiency by up to 30%

- Fully floating 2-piece construction

- Minimises brake fade and vibrations during longer driving

- Fastening system for brake disc and cap: D-Bobbin (10 screws)

- Great upgrade from non-directional, multi-disc OEM brake discs

Delivery includes:

- One pair (2 pieces) of Paragon Performance 350mm x 28mm, 2-piece brake discs for Dodge Challenger with hard/black anodised 6061-T6 aluminium pots, stainless steel bobbins and anti-rattle clips (assembled and ready to install)

- Detailed installation instructions

Mopar comparison number: 05290538AE

Old part numbers: 5290538AA, 5290538AB and 5290538AC, 5290538AD

Fits:

| Make | Model | Engine | Variant |

| Dodge | Challenger | 6.4 SRT | 2015 - 2023 |

| Dodge | Challenger | 6.2 Hellcat | 2015 - 2023 |

The price refers to 2 brake discs (one pair).

Reviews

There are no reviews yet